Регистрация в Леон. Открыть игровой счет. Рабочий домен

Регистрация на сайте Леон — необходимый шаг, для того что бы начать делать ставки на спорт в этой букмекерской конторе. Мы рекомендуем букмекерскую контору и Леон и уверенны в ее надежности, поэтому подготовили для Вас подробное руководство по регистрации.

Кроме того советуем почитать про текущие бонусы Леона . Если вы решили открыть игровой счет в букмекерской конторе Леон, то эта инструкция поможет вам пройти все этапы регистрации без каких либо проблем и приступить к ставкам.

Прежде всего, перед регистраций убедитесь что вы не регистрируетесь второй раз, в случае если вы уже открывали счет под ваши личные данные — букмекерская контора оставляет за собой право блокировать счета клиентов, согласно Правилам, расположенным на официальном сайте бк Леон . Если все в порядке и вы регистрируетесь в первый раз, то перед тем как нажать кнопку «Зарегистрироваться в бк Леон» убедитесь что вы соблюдаете следующие ниже изложенные правила.

Ссылка для регистрации:

ПРОМОКОД:BETTING-PROGNOZ

Правила регистрации в БК Леон:

- Вам исполнилось 18 лет (для граждан России и стран СНГ, кроме Беларуси и Казахстана)

- Вам исполнился 21 год (для граждан Беларуси и Казахстана)

- Вы открываете счет в первый раз

- Вы используете действительные паспортные данные

- Осознаете что ставки на спорт не являются гарантированным способом заработка и связаны с риском финансовых потерь

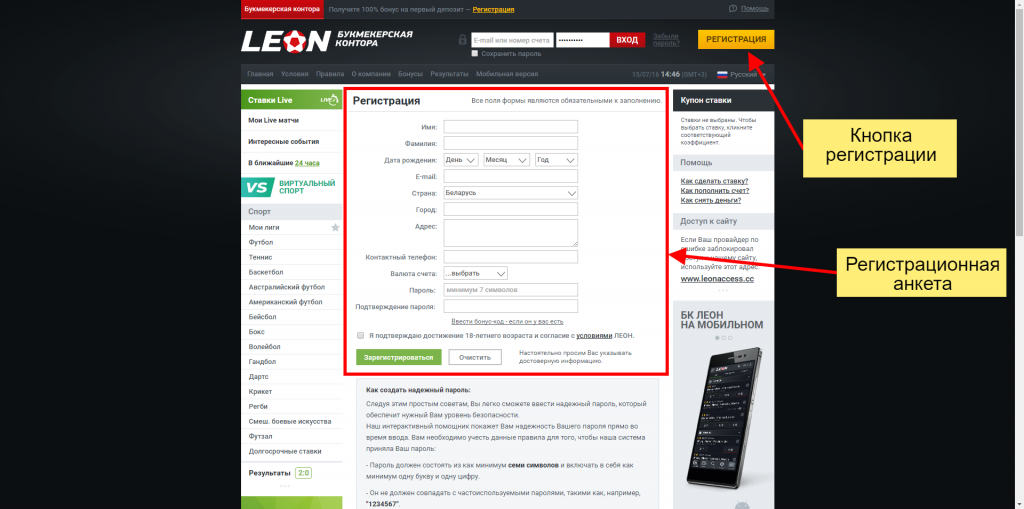

Заполнение регистрационной анкеты

Разберем подробно как заполнить анкету для регистрации в тотализаторе Леон. Для начала ознакомимся с ней.

- Анкета заполняется на русском языке

- Используем только свои паспортные данные

- Выбираем валюту счета

- Придумываем пароль

- Подтверждаем что исполнилось 18 лет

- Нажимаем кнопку «Зарегистрироваться»

- Подтверждаем электронную почту

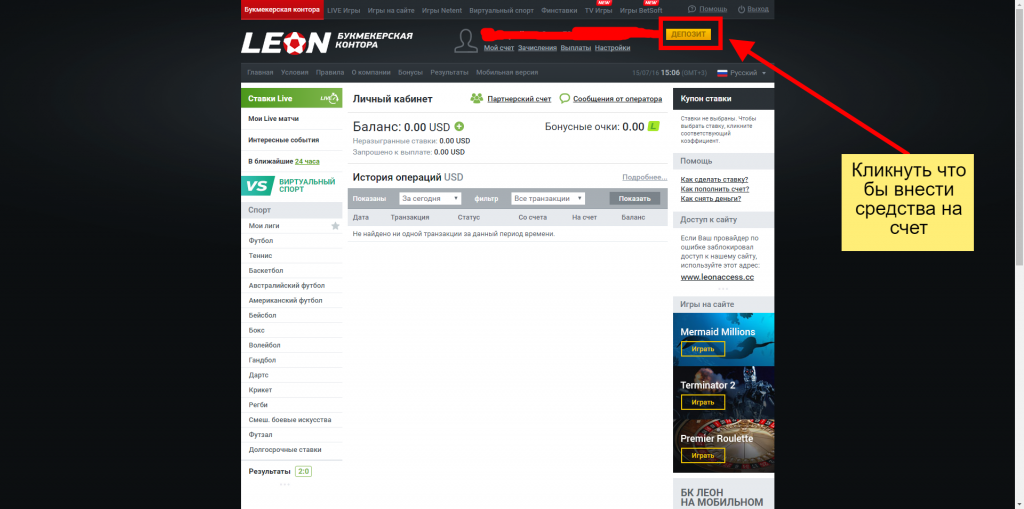

Что делать после регистрации в Леоне

- После регистрации в бк Леон потребуется внести депозит, для этого нажмите кнопку внести депозит, как на скриншоте:

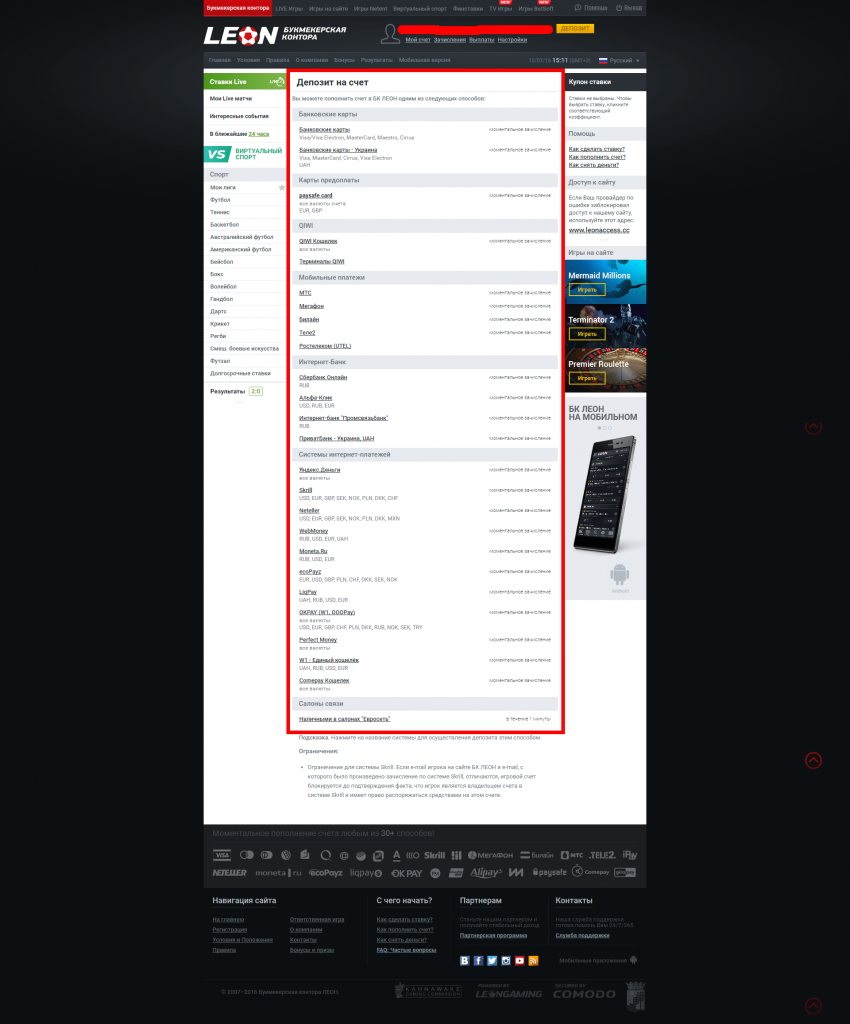

2. Выбираем способ пополнения:

3. Вносим средства на счет, после зачисления можно делать ставки.

Прохождение верификации в БК Леон

Для проверки регистрационных данных и в целях противодействия незаконным и мошенническим действиям потребуется отправить копии документов на электронную почту бк Леон, оповещение о необходимости пройти верификацию придет на регистрационный Email, поэтому заранее приготовьте сканы следующих документов:

- Последнюю страницу паспорта

- Страницу с пропиской

- Договор с мобильным оператором

Более подробную статью о прохождении верификации можно почитать тут.

Краткий обзор букмекерской конторы Леон

Букмекерская контора Leonbets онлайн осуществляет свою деятельность с 2007 года, продолжая развиваться и по сей день. Сегодня это один из самых известных и крупнейших тотализаторов на территории СНГ. Функционирует по лицензии Kahnawake Gaming Commission, что доказывает авторитет компании.

В основном тотализатор Леон предпочитают новички. И это понятно: незамысловатый сервис, низкие коэффициенты, весьма скудное информационное поле и плохо проработанная роспись ставок не привлекает опытных любителей беттинга. А для того чтобы «набить руку», начинающему игроку сервис предельно понятен.

Сайт построен по принципу «чем проще, тем лучше». Поэтому даже далёкому от игрового пространства человеку будет всё понятно. Делать ставки можно также из мобильных приложений для платформ iOS и Android, а также из мобильной версии сайта.

Видеоинструкция как зарегистрироваться в Леон с бонусом:

Для новоприбывших в мир азартных игр и ставок предусмотрен приветственный бонус. Также всем игрокам предложена программа лояльности, присоединившись к которой, можно накопить «леоны» и обменять их на сувенирные товары или эквивалентную денежную сумму.

Сервис тотализатора бк Леон поддерживает множество методов вывода денежных средств со счёта. На электронные платёжные системы суммы переводятся почти мгновенно, а в случае с банковской картой срок ожидания может достигнуть 3 дней.

Обвинения в мошенничестве, уже ставшие традицией для букмекерских контор, не обошли стороной и эту, значительно подпортив отзывы тотализатора Леон. Но помимо этого, были также замечены жалобы на несовершенство систем безопасности аккаунтов и счетов пользователей.

Некоторые игроки утверждают, что с их счёта были украдены деньги. Жалобы были приняты службой поддержки, в данный момент расследования по делам ещё ведутся, а пострадавшим остаётся лишь надеяться на добросовестную работу специалистов.

Секрет популярности тотализатора Леон в завышении лимитов для совершения ставок «на фаворита», чего у многих конкурентов сервиса не найти. Максимальная ставка тоже не может не порадовать любителей играть по-крупному, ведь она составляет 10 тысяч долларов. Привлекает внимание бетторов и новостная лента, оповещающая о предстоящих событиях, а также новинки в линии ставок: «Азиатский гандикап» и «Двойной исход».

В целом, тотализатор Leonbets можно охарактеризовать как сервис, чей слоган мог бы звучать как «Ничего лишнего, только игра». С одной стороны простота сайта и низкие коэффициенты многим могут показаться пережитками прошлого, а с другой — ничего не отвлекает бетторов от игры, и позволяет лучше прочувствовать момент ожидания выигрыша.

На этом все, после прочтения этой статьи вы пройдете регистрацию в бк Леон правильно. Желаю удачи!

Другие букмекерские конторы:

Если вам хотелось бы попробывать играть в других букмекерских конторах — мы предлагаем широкий выбор обзоров:

- Париматч — рабочий домен, полный обзор, бонус при регистрации

- William Hill — как получить бесплатную ставку 25$

- Рабочий домен Leon, как начать ставить в Леоне

Flashscore.com.ua

В 2020-м Тимати начал сотрудничать с БК «Леон». Точная сумма контракта и его длительность не раскрываются. Контора уже использовала фотографии рэппера во время проведения промоакции «Своих не бросаем» и собирается организовать несколько конкурсов с участием артиста. Главным призом одной из бонусных программ станет Mercedes. Поэтому, судя по всему, внедорожник появился в клипе неспроста.

Нижний Новгород Коминтерна 105

Распределение призового фонда пройдет по формуле:

А в приложении букмекера все новые пользователи могут забрать бездепозитный фрибет на 500 рублей. Таким образом, приветственный бонус Леон для новых игроков может достигать 25 500 рублей.

Бонусы на матч от партнеров

Откуда еще найти это Leonbets Скачать Бесплатно На Телефон ищут:

- Бк Леон Минимальный Вывод

- Бк Леон Пк

- Бк Леон Не Выплачивает

- Пополнить Счет В Бк Леон

- Ставки На Спорт Леон Отзывы

Полученный фрибет нужно использовать в течение 72 часов после начисления. Можно заключить пари типа «экспресс» или «ординар» с коэффициентом от 1,70 до 3,00. Обратите внимание, что использовать фрибет можно на событие, которое завершится не позднее, чем через 72 часа с момента получения бонуса.

DanTri.com.vn — Dan Tri Balo Studios · Новости и журналы

Дата рождения ― один из главных и обязательных пунктов регистрационной анкеты для новичков. В случае, если клиент укажет возраст менее 18 лет, в создании профиля ему будет отказано.